Cape Cod has long been synonymous with fishing. Yet up until the widespread adaptation of refrigeration and icing, the fishing industry was reliant upon salt to preserve its catch, simply put without salt there would have been no fishing. Before the railroad, the only economical way to supply salt was to produce it locally. In an area like Cape Cod, this meant evaporating seawater in coastal saltworks and copious amounts of salt were needed. For two centuries salt-works lined the Cape Cod coastline on an industrial scale. Salt-works were a ubiquitous part of the Cape Cod’s coastal landscape and were present in every significant settlement on Cape Cod. In period accounts salt works are described as lining the shorelines of Chatham and bay-side of Provincetown and N. Turo to support the large fishing fleets based in Provincetown and Chatham.

Salt works were so vital to New England’s economy that when the British attacked Wareham during the War of 1812 they targeted the saltworks and burnt them to the ground. Anytime a large number were damaged it could have a profound impact on the area. Most notably The October Gale of 1841 destroyed most of Cape Cod’s salt works. This in addition to the damage to the fishing fleet suffered led to a profound economic slump until they were rebuilt and producing salt once again. Salt remained vital to the area’s economy until the widespread availability of ice and refrigeration to preserve the catch. By the turn of the century, Cape Cod salt works industry was a distant memory as the arrival of the railroad enabled the transportation of inexpensive rock-salt to Cape Cod’s fishing harbors. Within the last decade, a couple of artisanal salt-works have opened. If you are interested in local sea salt check out the Wellfleet Sea Salt Company their salt is also used by a large number of local artisanal products.

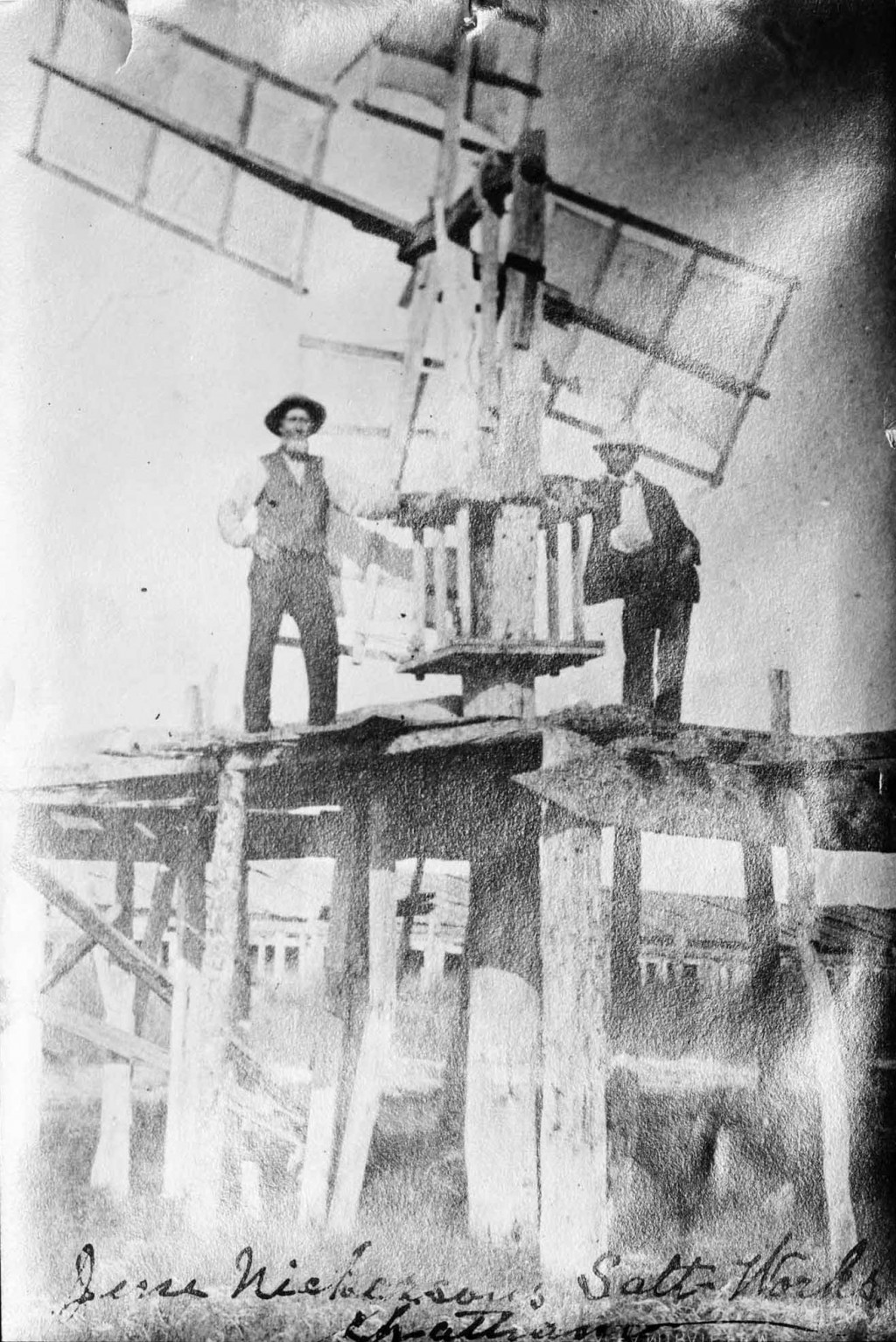

Today when we think of windmills on Cape Cod, we think of the large grain mills that are preserved today. These were far outnumbered by the smaller windmills that were used to pump salt water into the evaporating tanks of the salt works. The above picture is of John Nickerson’s windmill at his salt works in Chatham.

Here the two most common types of water pumps used by salt works on Cape Cod are diagrammed. These were used to pump seawater up into the evaporation vats (tanks). The one to the left is a tidally driven water wheel pump and in the center the more conventional windmill pump. Sea water would only be drawn on the incoming tides. Outgoing tides have a lower salt content because of the freshwater inflows from springs, creeks, and streams.

These operations could be quite large, here the evaporation vats of Enoch Harding’s Salt Works in Chatham stretch out to cover the majority of the beach. If you look closely, you can see salt encrusting the sides of the left-hand tanks and Fleur de Sel forming. Also, note the dunes in the background, one thing that you notice in all old photos of Cape Cod is the lack of trees. Cape Cod was quickly denuded after it was initially settled by Europeans, and it remained this way up until the 1960-1970s, most of Cape Cod’s trees date to around this time. This lack of vegetation meant that sand moved at a much greater rate than it does today, this combined with the hardening of Cape Cod’s shoreline means that accretion of sand happened at a faster rate than would today leading to wider coastal sand shelves.

The evaporation vats had covers that would be closed during inclement weather to ensure that rainfall would not dilute the salt solution. The covers would be left opened to allow for the water to evaporate by the sun. They were on rollers enabling them to be opened and closed easily.

Evaporation vats were commonly used in series starting with the first vat that seawater was pumped into. There it was left to evaporate for four to six weeks depending on the weather. From there concentrated brine would go into the “pickling” vat where it was left to evaporate further. Once crystals started to form the concentrated brine would then be transferred into the “salt vat.” There it would crystallize further allowing for it to be skimmed or raked. This entire process would take months. After the initial pumping of the seawater into the first vat all the remaining transfers were gravity fed. As soon as the first vat was drained, it would be refilled. With the amount of time, it would take to get to a finished product it was important to constantly be refilling the empty vats with new water. The time it took to arrive at a finished product is why any disruption due to storm damage had such an impact on the local economy because it would take months to complete a cycle. The salt works on Cape Cod were operational during the spring, summer, and early fall. With the most productive months being the summer months. They were labor intensive and thus uneconomical once the railroads were built bringing in the much cheaper mined rock-salt. This transition was not a localized event. The transition from shoreline locally based evaporation based salt works to mined rock salt played out globally with the introduction of the railroad.

Here is a map of salt works in Chatham circa 1810. It shows just how common salt works were on Cape Cod. It is also interesting to compare this to the present day shoreline and to see what these locations are like now. Chatham’s coastline constantly in flux and is remarkably different from the shoreline of two centuries ago. Below is a map showing the present day shoreline of Chatham.

This is the Enoch Harding salt works that were located in Chatham at Buck’s Creek. It was built on & pier where fishing boats could tie up and offload their catch and then put on fish drying racks. Below is the present day location of this salt works.